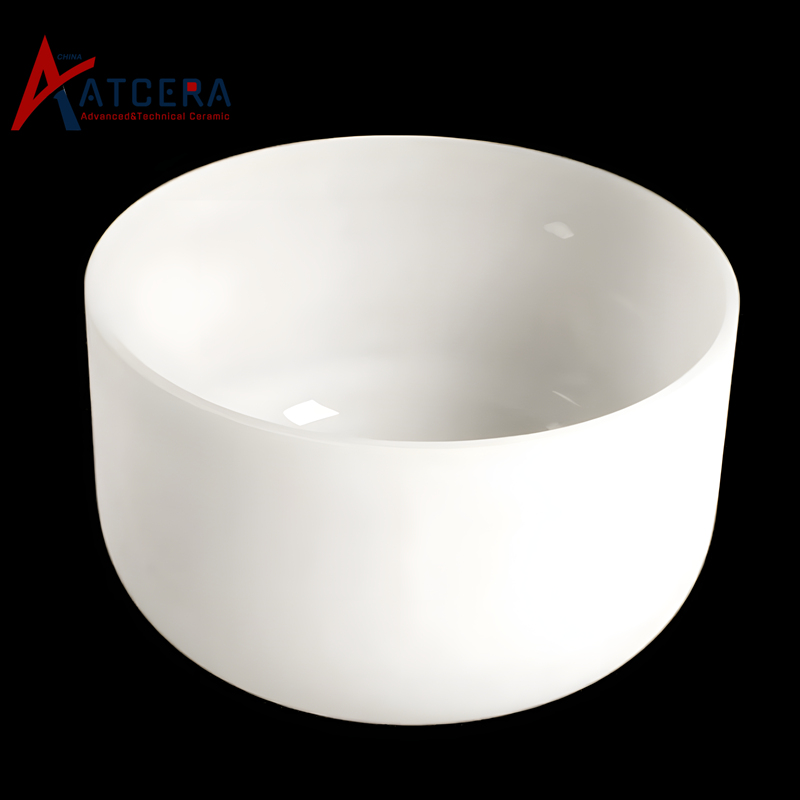

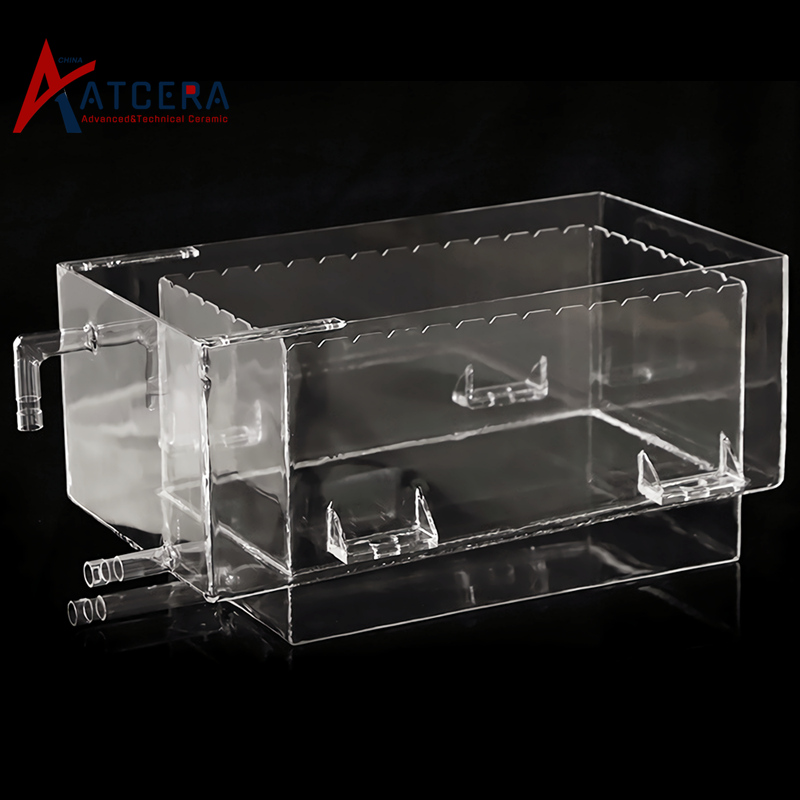

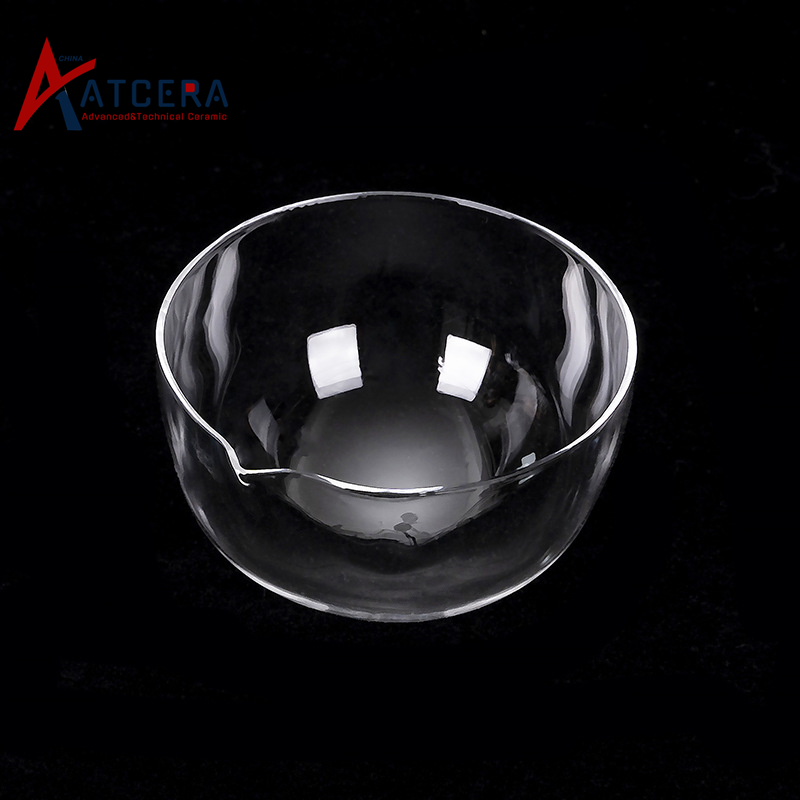

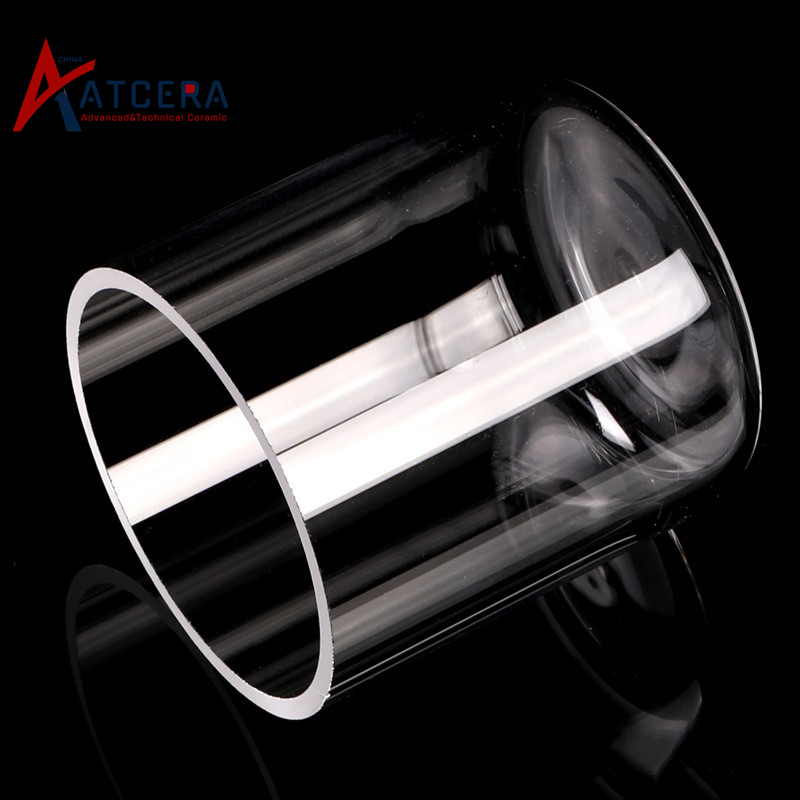

Quartz crucible is a container made of high purity quartz sand (99.9%|99.99%99.999%), with properties of super clean and high temperature resistance, performance under high temperature is quite stable, in semiconductor and Laboratory field has an important application, it is used to contain molten silicon, to pull silicon crystal rod for the subsequent process.

As a manufacturer of quartz crucibles, ATCERA offer factory-direct pricing to ensure you get the best value without the middleman mark-up.

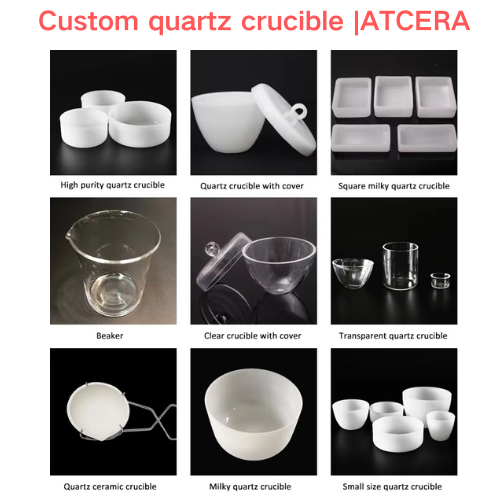

| view all quartz glass crucibles |