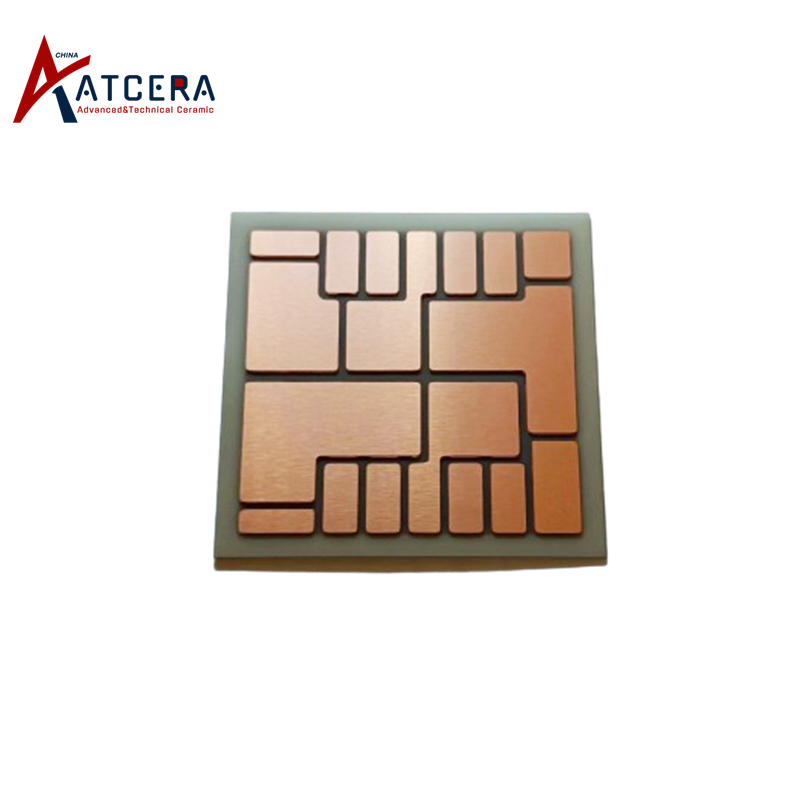

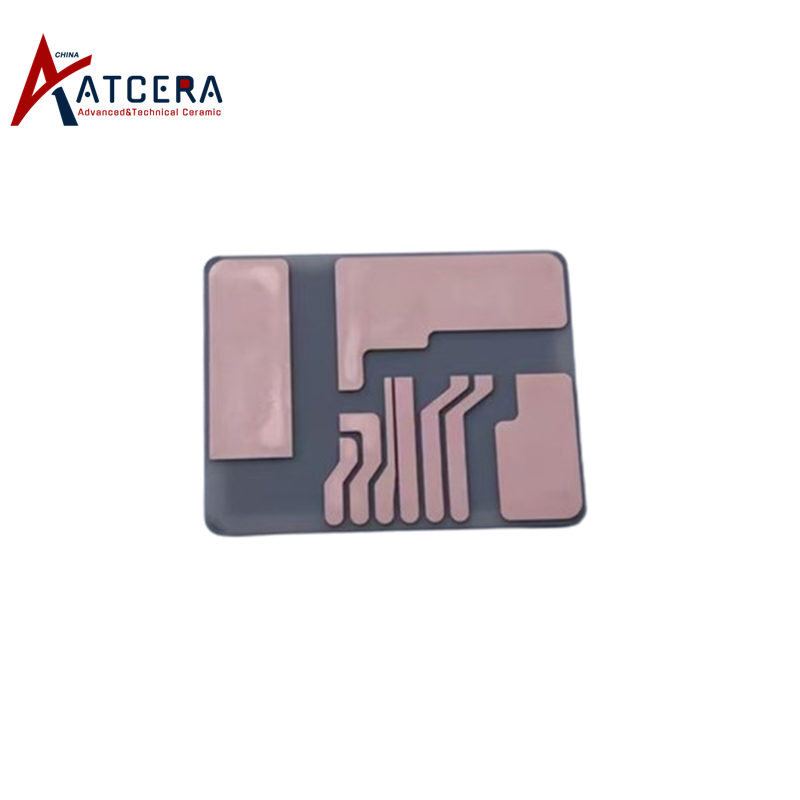

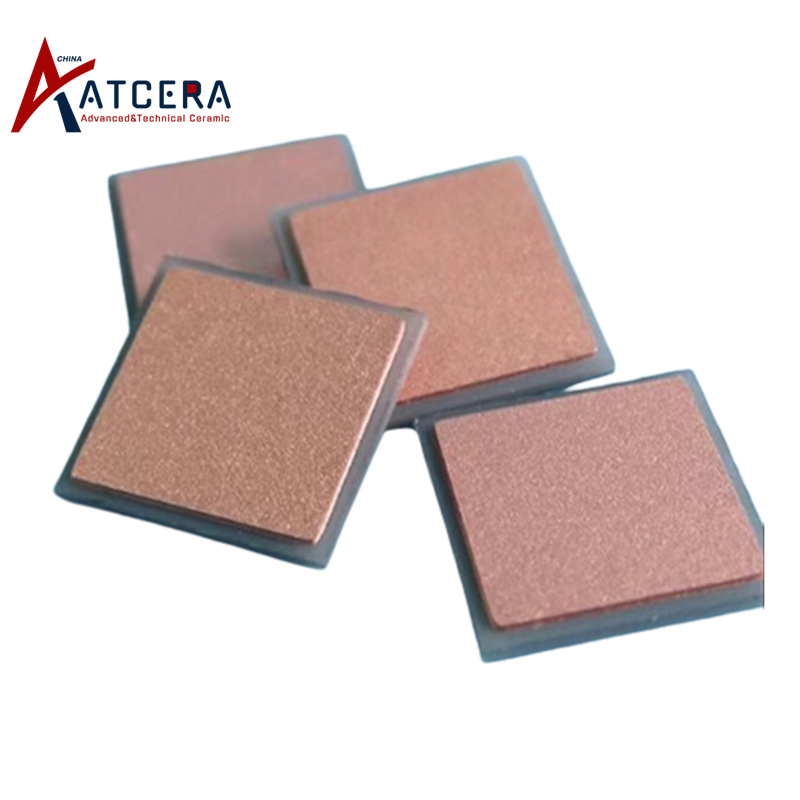

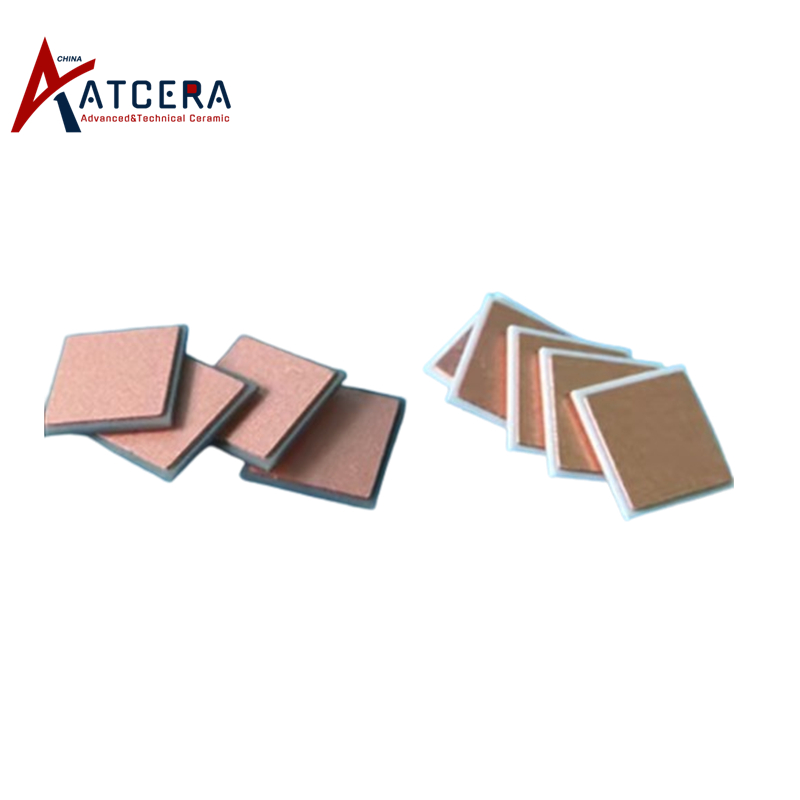

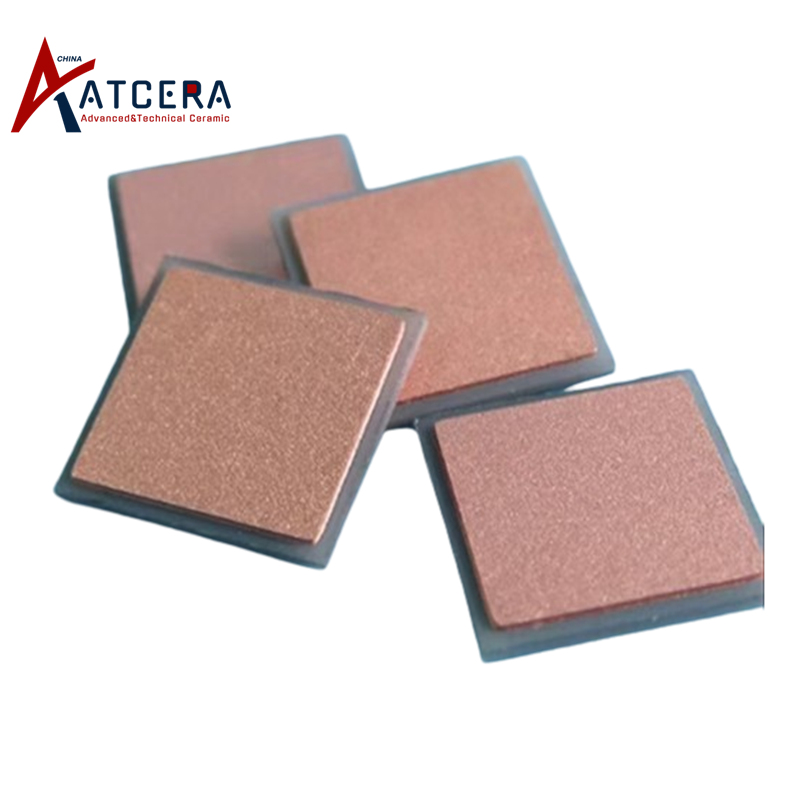

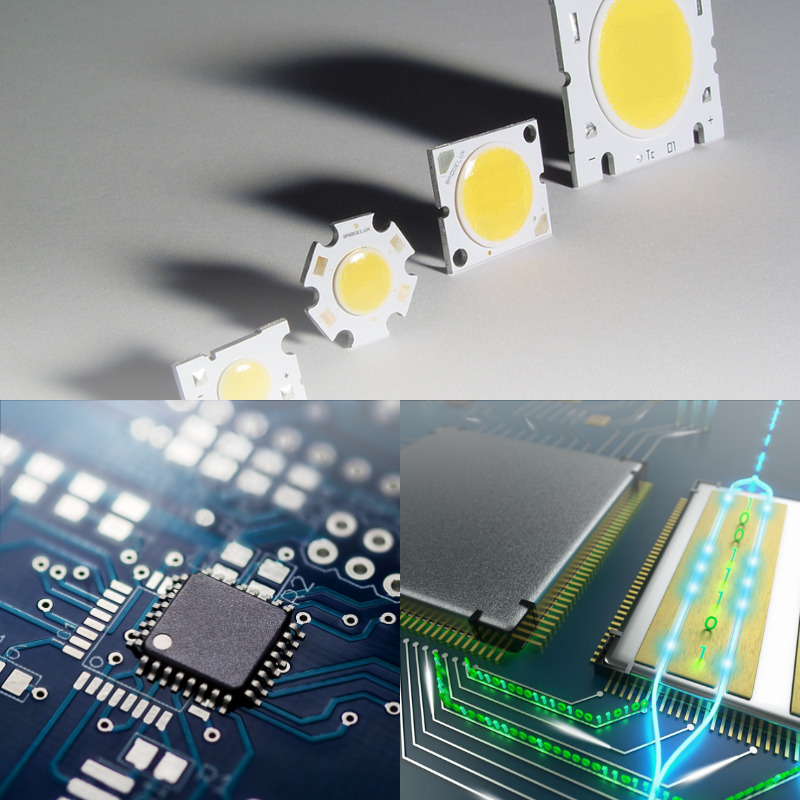

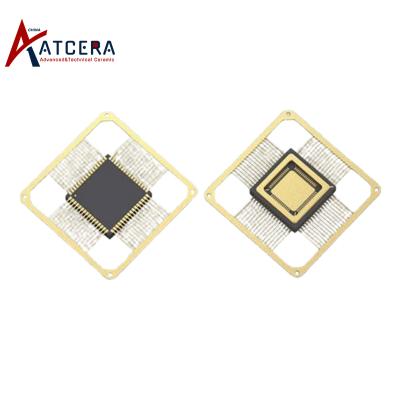

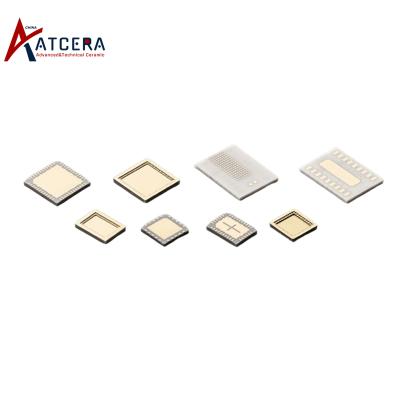

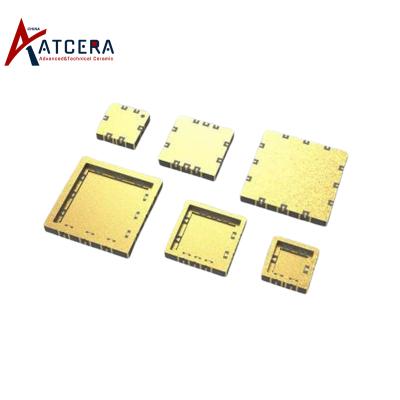

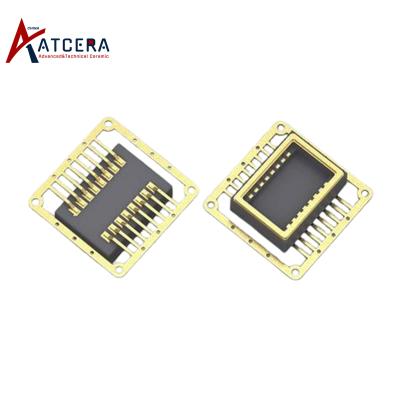

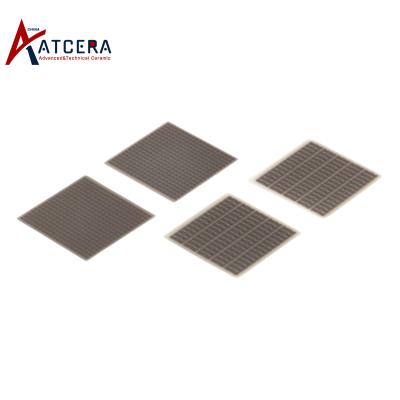

Metalized aluminum nitride ceramic substrate is an aluminum nitride ceramic substrate with copper-bonded metalization, it has electrical function and high insulation properties, also with high temperature resistance, good thermal shock resistance and fast heat conductivity. It is usually used as packaging substrate of high voltage, high power device, including power modules, high-frequency switching power supplies, relays, communication modules, LED modules, etc., which are widely used in electrical vehicles, rail transit, smart grid, aerospace and other fields.

Metalized aluminum nitride ceramic substrate can obtained by a variety of processes, combined with DBC (direct bond copper) process, that is, to form DBC aluminum nitride ceramic copper substrate, combined with DPC (direct plated copper) process to obtain DPC aluminum nitride copper substrate. Besides, TFC (thin film composite) and AMB (active metal brazing) processes can also be used, TFC aluminum nitride copper substrate and AMB aluminum nitride copper substrate are formed respectively.

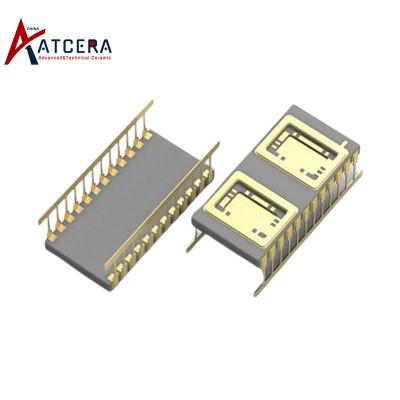

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.