Properties of Alumina Silicate Ceramic Fiber Board

1. High Pressure Resistance & Long Service Life

The Alumina Silicate Ceramic Fiber Board is designed to withstand high-pressure environments, providing exceptional durability and a long operational lifespan. This makes it ideal for use in demanding industries like steel manufacturing, petrochemical, and power generation, where performance longevity is critical.

2. Low Thermal Capacity & Low Thermal Conductivity

With its low thermal mass and outstanding thermal insulation properties, this ceramic fiber board effectively reduces heat loss and improves energy efficiency. Its low thermal conductivity makes it an excellent solution for high-temperature applications, ensuring superior heat retention and energy savings.

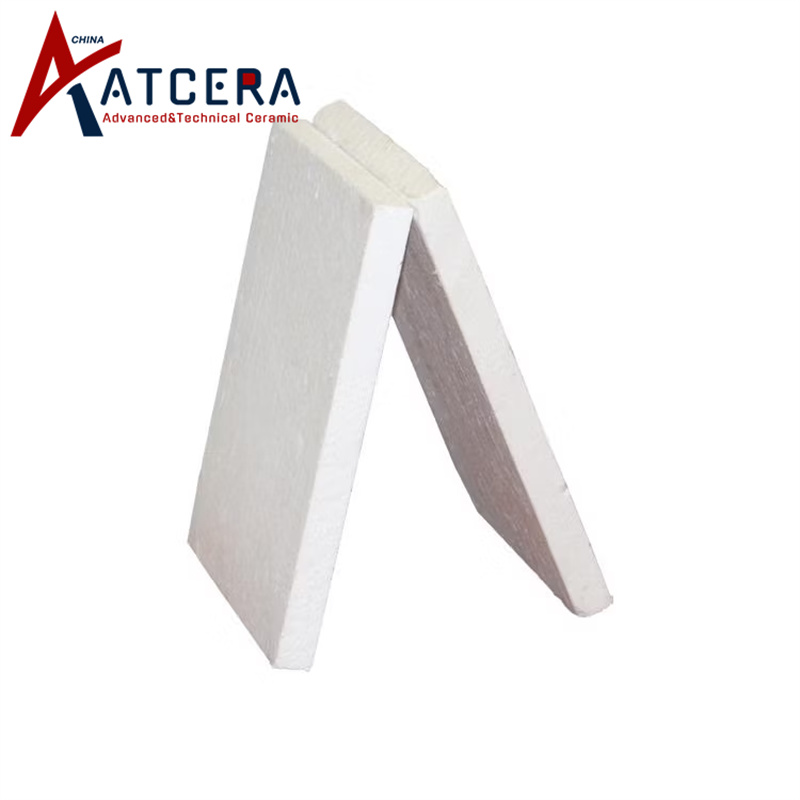

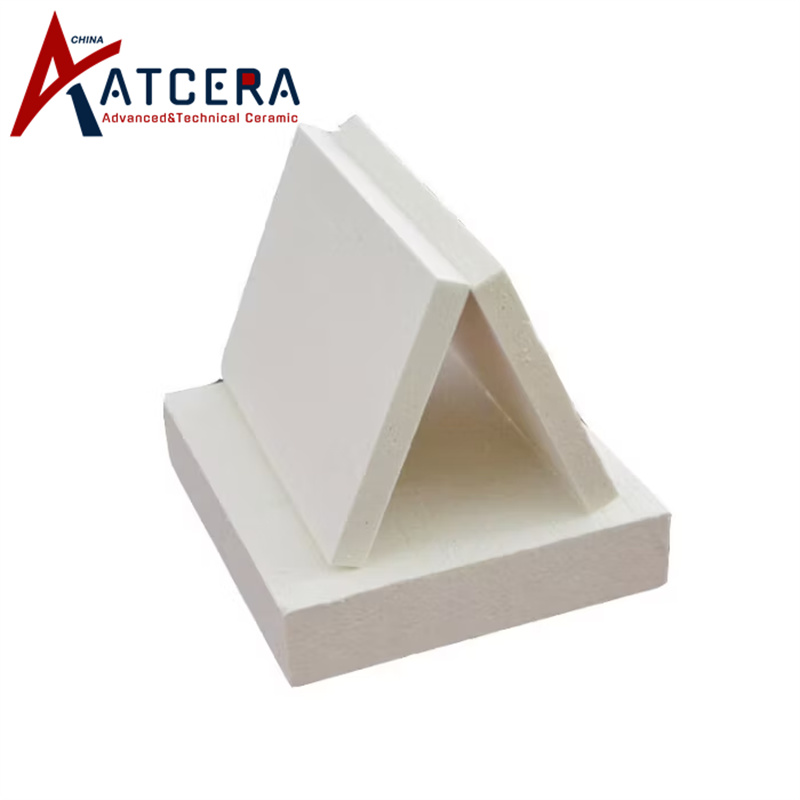

3. Tough, Non-Brittle Material with High Toughness

The Alumina Silicate Ceramic Fiber Board is made from a tough, non-brittle material that ensures reliable performance in environments subject to mechanical stress or impact. Its high toughness prevents cracking or shattering, making it suitable for both industrial and high-stress applications.

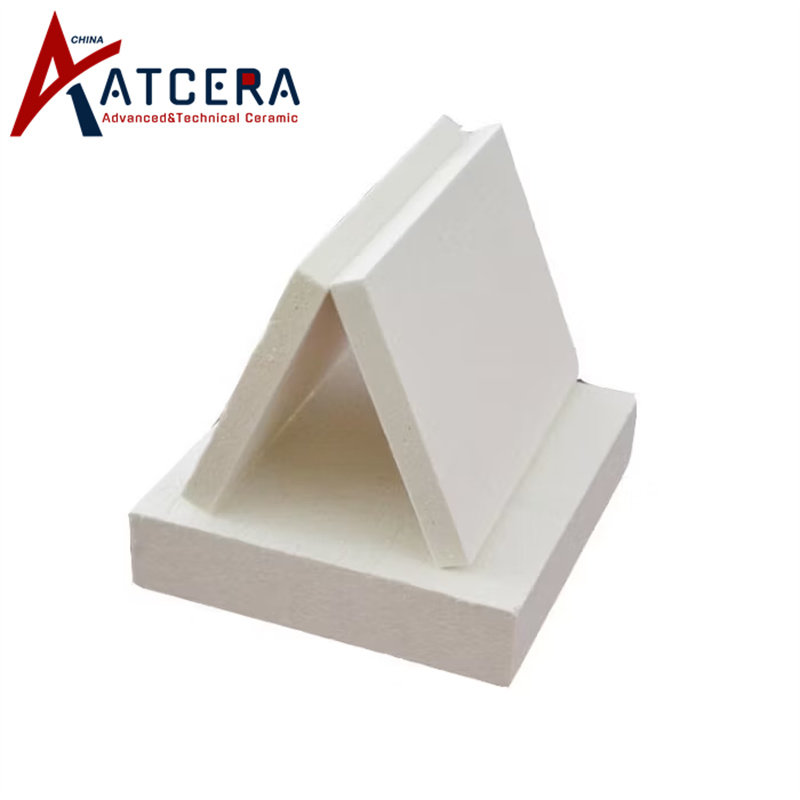

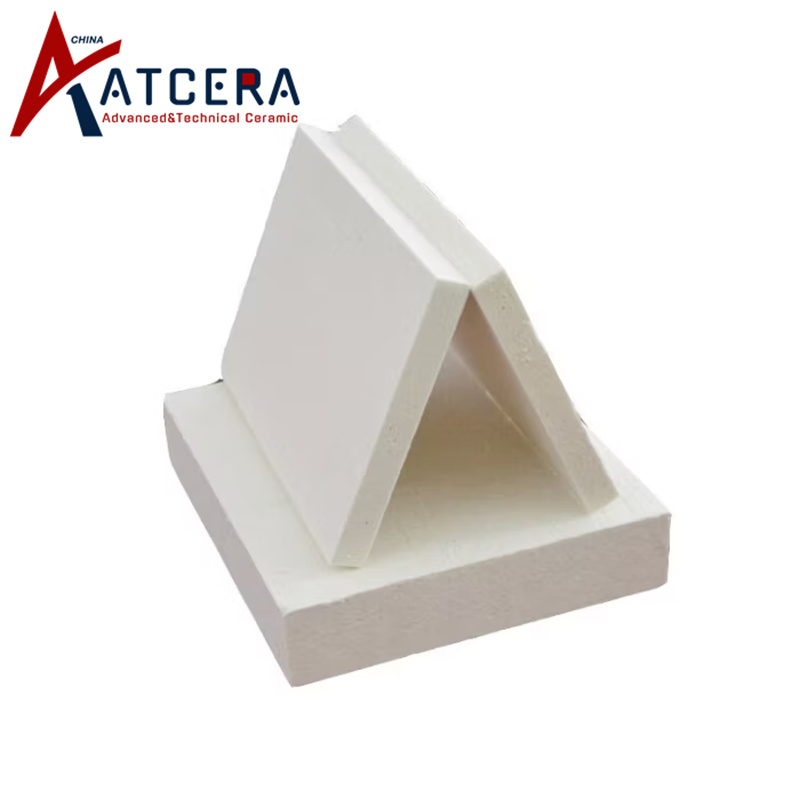

4. Precision Dimensions & Superior Flatness

Manufactured with precise tolerances, the ceramic fiber board offers excellent flatness and dimensional accuracy, ensuring a perfect fit for any application. This precision is essential in industries such as aerospace, manufacturing, and construction where precise material specifications are a must.

5. Easy to Cut, Install, and Handle

The Alumina Silicate Ceramic Fiber Board is lightweight and easy to cut, shape, and install, streamlining the construction and assembly process. Its ease of handling reduces labor costs and installation time, making it ideal for both large-scale projects and DIY installations.

6. Excellent Wind Erosion Resistance

This ceramic fiber board has outstanding wind erosion resistance, making it the perfect choice for outdoor applications or areas exposed to harsh weather conditions. Its durability ensures that it maintains its structural integrity and performance in windy and abrasive environments.

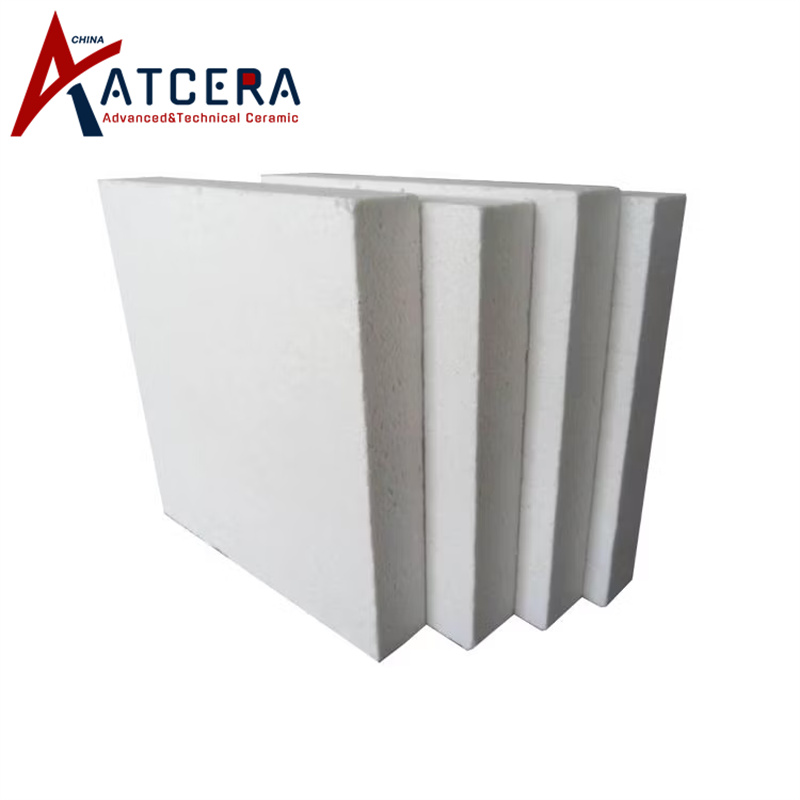

7. Consistent Quality & Uniform Fiber Distribution

Produced using advanced continuous manufacturing techniques, the Alumina Silicate Ceramic Fiber Board features a uniform fiber distribution that ensures consistent quality and stable performance across the entire product. This makes it a reliable choice for industries that require materials with predictable and stable characteristics.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.