Applications of Alumina Silicate Ceramic Fiber Blanket

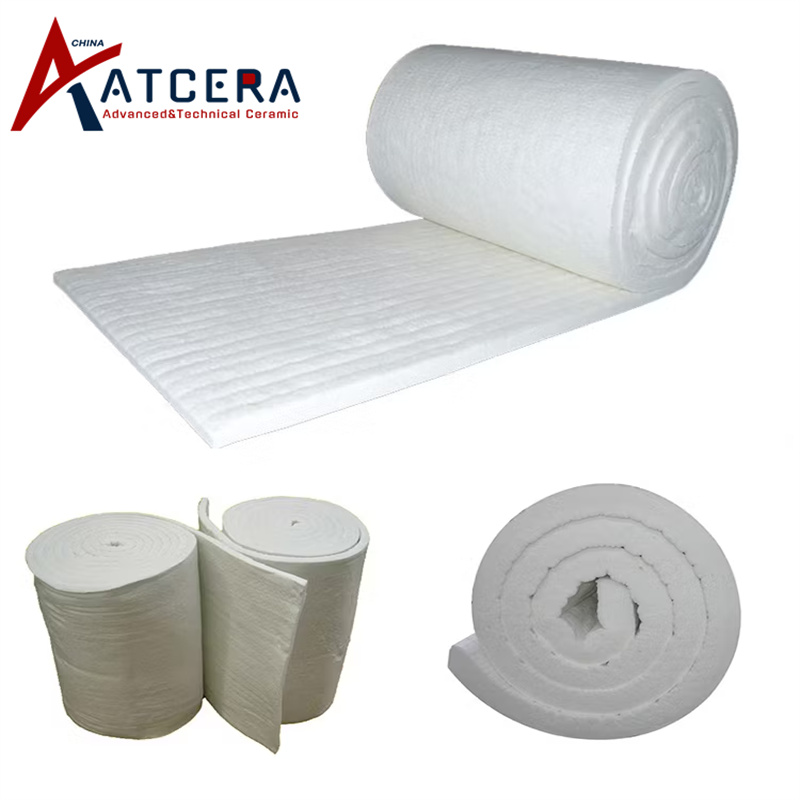

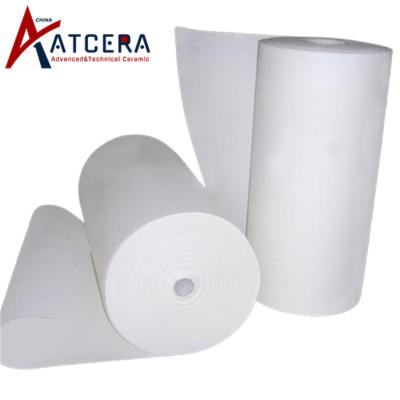

1. Versatile Raw Material for Fiber Blanket & Board Products

The Alumina Silicate Ceramic Fiber Blanket serves as an excellent raw material for producing ceramic fiber boards and blankets. It is ideal for creating insulation products used in a variety of industrial applications, including furnaces, kilns, and heat shields.

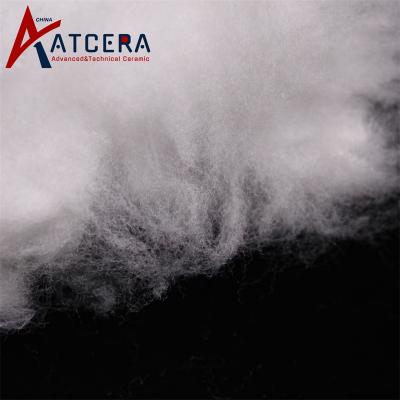

2. High-Purity Spun Fiber for Textile Applications

This ceramic fiber blanket is made from high-purity spun fibers, making it a preferred material for fiber textile products. These fibers are designed for use in the production of heat-resistant fabrics, ropes, and blankets, ensuring superior performance in extreme heat conditions.

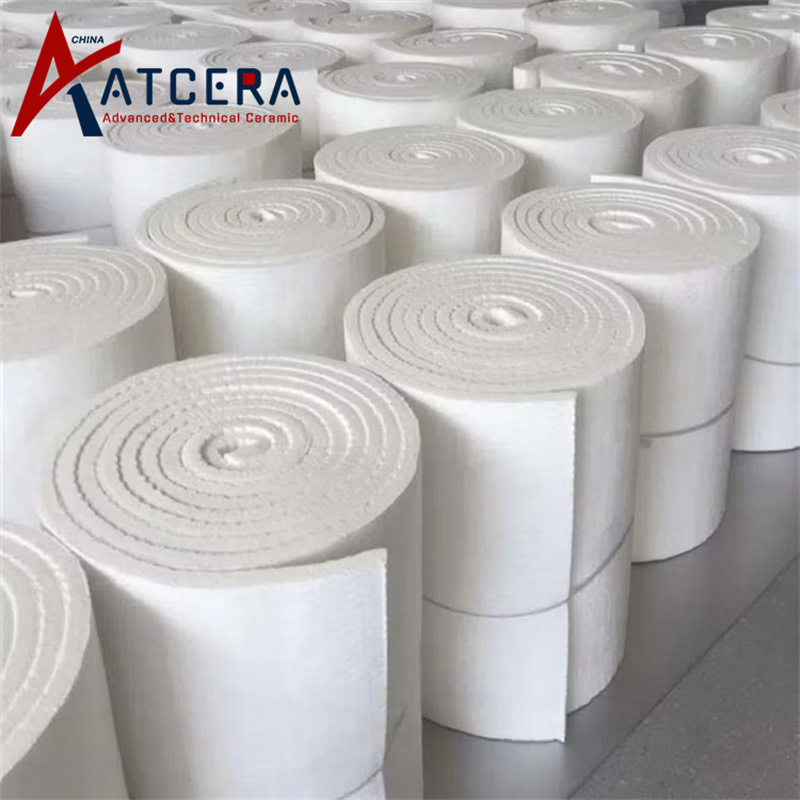

3. Ideal for High-Temperature Furnaces, Heaters, and Kilns

With its exceptional heat resistance, the Alumina Silicate Ceramic Fiber Blanket is commonly used in high-temperature furnaces, heating devices, and kilns. It is also highly effective as a joint sealant and gap filler in furnace linings, offering reliable insulation and thermal protection at elevated temperatures.

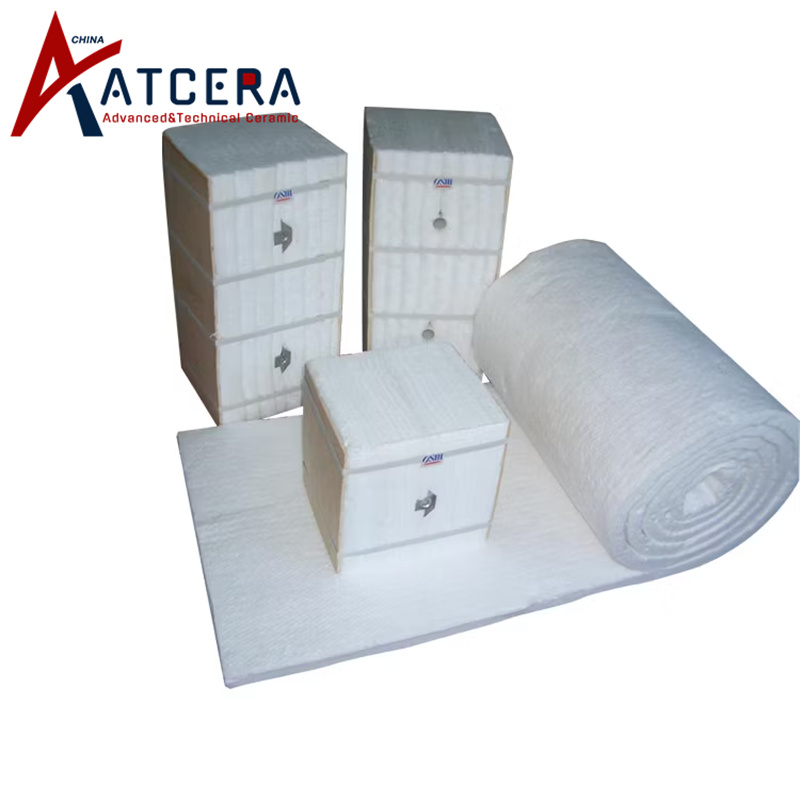

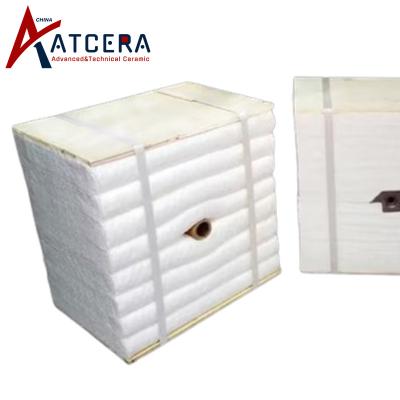

4.Raw Material for Wet Process Products

The ceramic fiber blanket is suitable as a raw material in the wet process for producing thermal insulation products. Its unique properties make it ideal for creating molds and shapes used in various applications, ensuring consistent performance in both dry and wet processes.

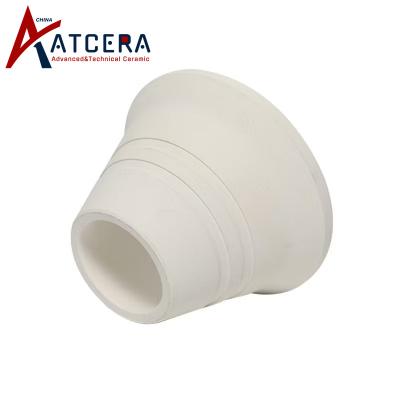

5. Fiber Spraying, Casting, and Coating Materials

This Alumina Silicate Ceramic Fiber Blanket can be used as a key component in the production of fiber spraying materials, casting compounds, and coating formulations. Its fine, uniform fibers ensure smooth application and optimal thermal performance when used in various industrial processes.

6. Thermal Insulation for Complex Spaces & Edges

The ceramic fiber blanket is also used as a thermal insulation material for filling edges and complex spaces in high-temperature environments. Its flexibility and ease of use make it perfect for insulating hard-to-reach areas, providing excellent heat retention and energy efficiency.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.