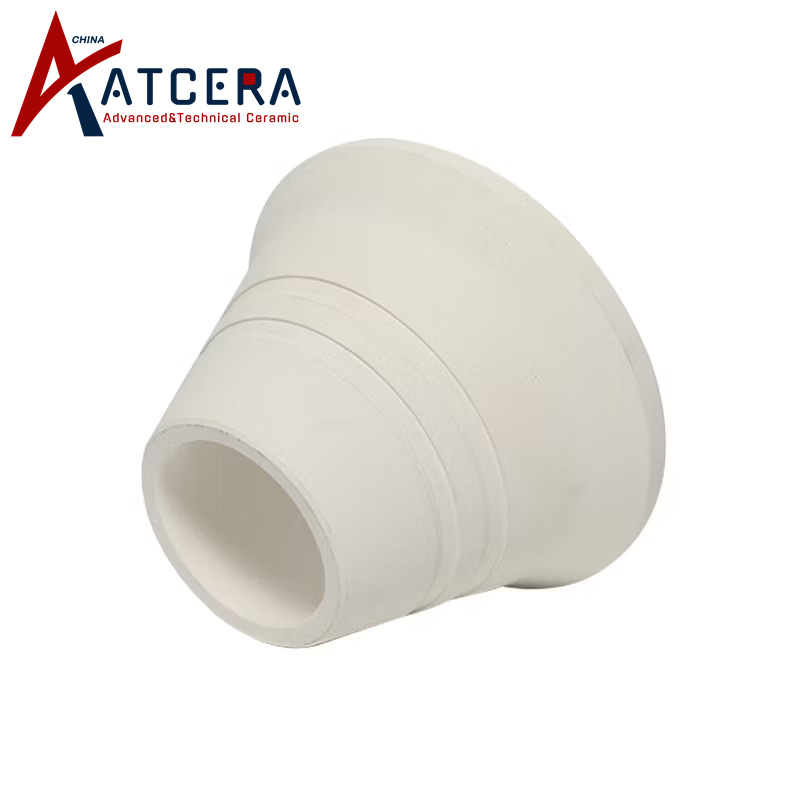

Properties of Aluminum Silicate Ceramic Pouring Cup

1. Excellent High-Temperature Stability

The Aluminum Silicate Pouring Cup demonstrates remarkable stability at elevated temperatures, ensuring no peeling or detachment, making it ideal for applications requiring consistent performance under heat.

2. Outstanding Thermal Shock Resistance

Designed to withstand rapid temperature changes without cracking or damaging, this pouring cup exhibits superior thermal shock resistance, suitable for demanding casting processes where temperature fluctuations are frequent.

3. High Strength & Abrasion Resistance

With its robust construction, the Aluminum Silicate Pouring Cup is highly resistant to erosion and wear, ensuring long-lasting durability and performance even in harsh, high-velocity pouring environments.

4. Slag & High-Temperature Corrosion Resistance

Engineered to resist the corrosive effects of slags and high temperatures, this pouring cup maintains its integrity and functionality, minimizing the risk of contamination and extending its service life.

5. Superior Thermoplasticity at High Temperatures

The Aluminum Silicate Pouring Cup offers excellent thermoplastic behavior at high temperatures, effectively cushioning thermal stresses and reducing the adherence of slag, leading to smoother and more efficient casting operations.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.