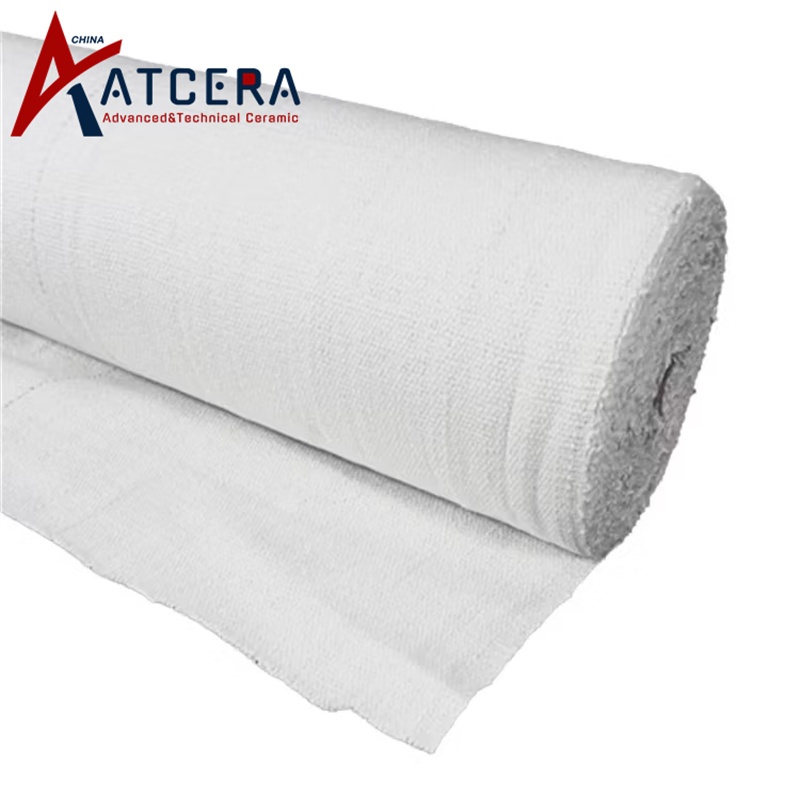

Applications of Aluminum Silicate Ceramic Fiber Cloth

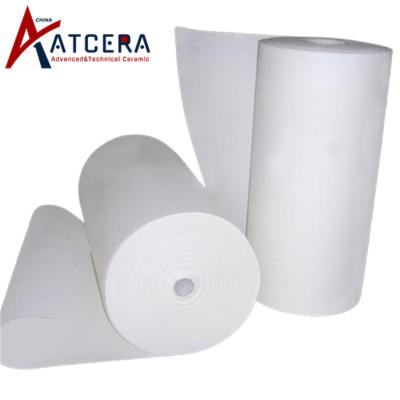

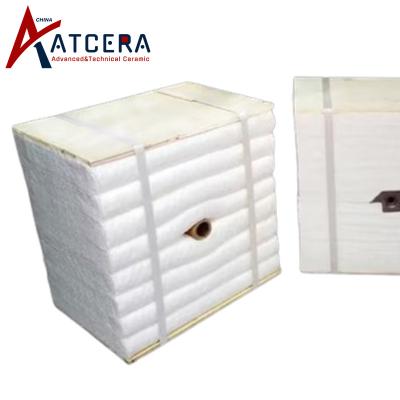

1. Versatile Insulation for Industrial Furnaces, Pipes, and Containers

The Aluminum Silicate Ceramic Fiber Cloth is designed for superior thermal insulation in various industrial furnaces, high-temperature pipelines, and containers. It effectively retains heat, reducing energy consumption and enhancing operational efficiency, aligning with the needs of European and North American industries seeking sustainable and cost-effective insulation solutions.

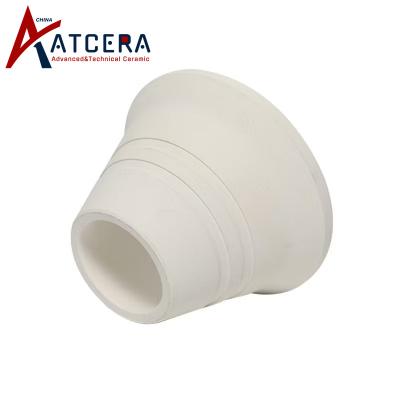

2. Sealing and Protection for High-Temperature Applications

Ideal for sealing furnace doors, valves, and flanges, as well as serving as a material for fire doors, fire shutters, and high-temperature furnace curtains, this cloth ensures tight seals and prevents heat loss, enhancing safety and performance in high-temperature environments.

3. Thermal and Fire Protection for Engines, Instrumentation, and Cables

The cloth is perfect for insulating engines and instrumentation, providing a protective barrier against heat and fire. Additionally, it serves as a durable wrapping material for fire-resistant cables, ensuring the integrity and safety of electrical systems in harsh conditions.

4. High-Temperature Fabrics and Fillers for Various Applications

Suitable for use as insulation coverings, high-temperature expansion joint fillers, and smoke duct linings, the Aluminum Silicate Ceramic Fiber Cloth offers exceptional durability and thermal resistance, making it a versatile choice for a wide range of industrial applications.

5. Personal Protection and Advanced Applications

This cloth is also utilized in the production of high-temperature personal protective equipment, such as fire-resistant clothing and high-temperature filters. Its ability to replace asbestos in various applications makes it a safer and more environmentally friendly alternative, meeting the stringent health and safety standards of European and North American markets.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.