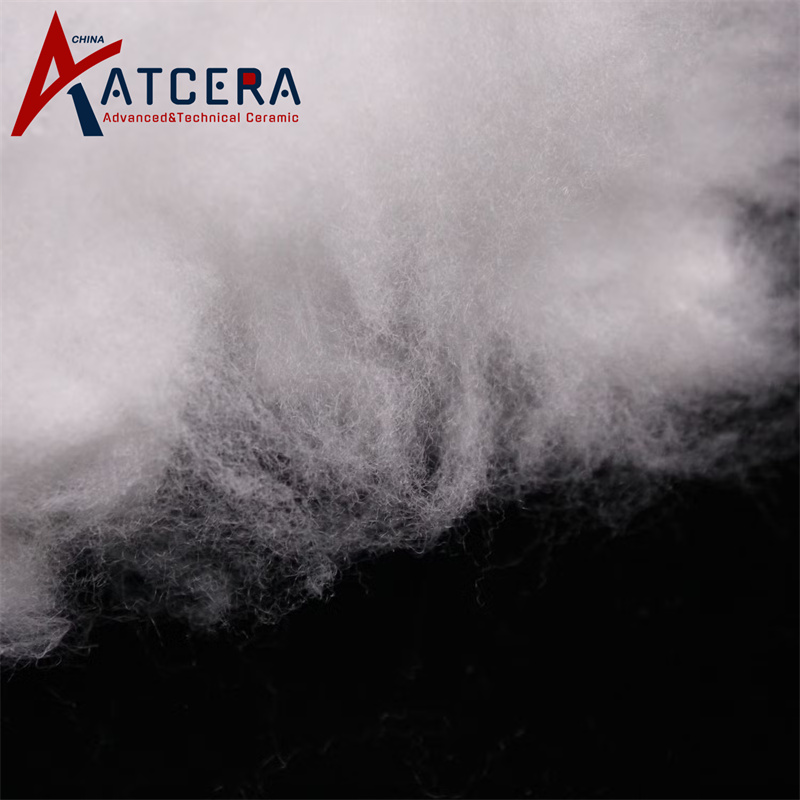

Applications of Aluminum Silicate Ceramic Fiber Wool

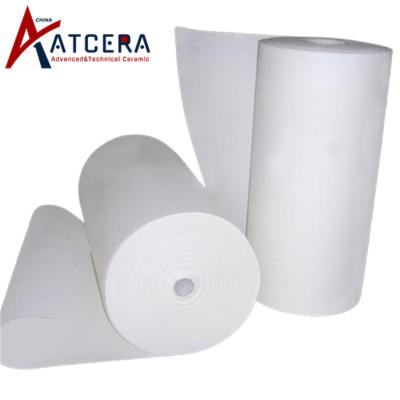

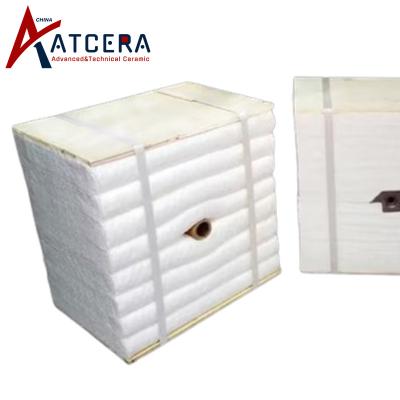

1. Fiber Blanket & Board Manufacturing

Our silicon aluminate fiber wool serves as a premium raw material for producing fiber blankets and boards, offering exceptional thermal insulation and fire resistance for a wide range of industrial applications.

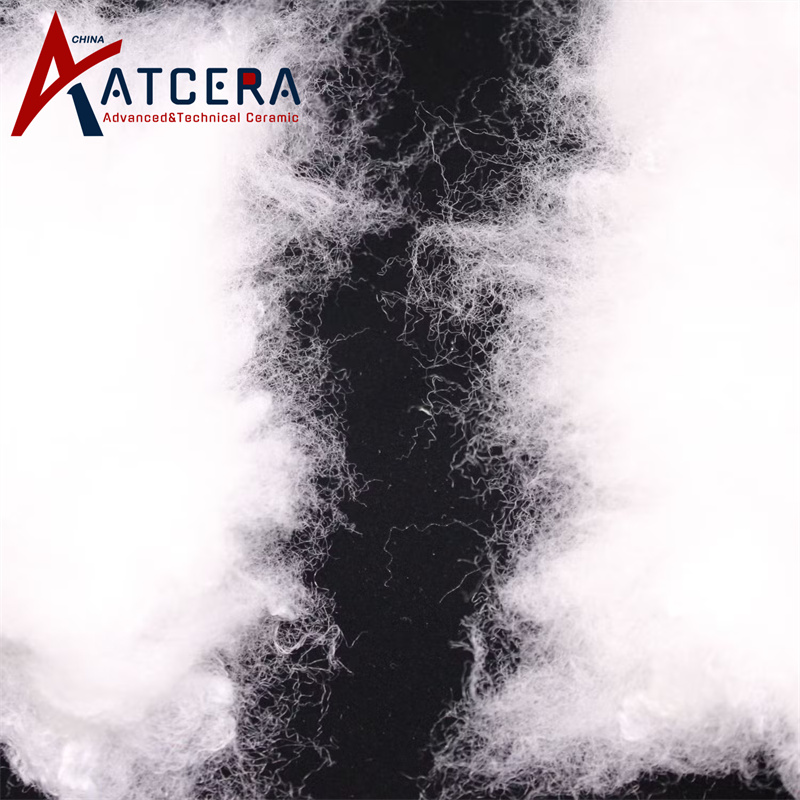

2. High-Temperature Furnace & Heating Equipment Linings

Ideal for use as a gap filler in high-temperature furnaces, heating devices, and wall linings, this ceramic fiber wool ensures effective heat retention and reduces energy consumption.

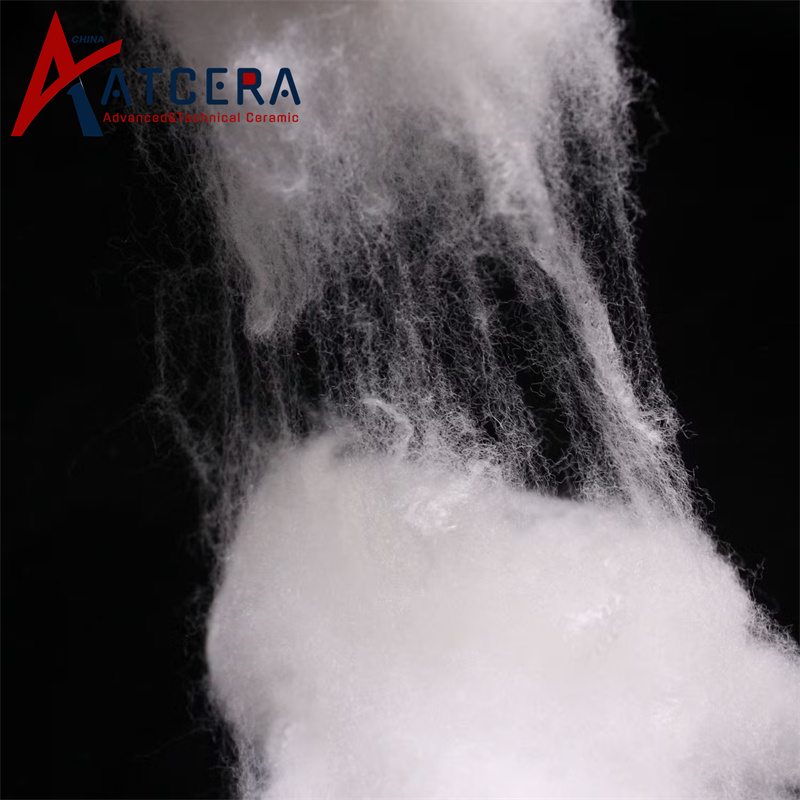

3. Wet-Process Products Raw Material

As a versatile raw material for wet-process products, our fiber wool enhances the durability and insulation properties of various industrial materials, making it a go-to choice for demanding applications.

4. Fiber Spraying, Casting, & Coating Materials

Suitable for fiber spraying, casting, and coating applications, this silicon aluminate fiber wool provides a seamless, high-performance insulation layer, ensuring optimal performance in extreme conditions.

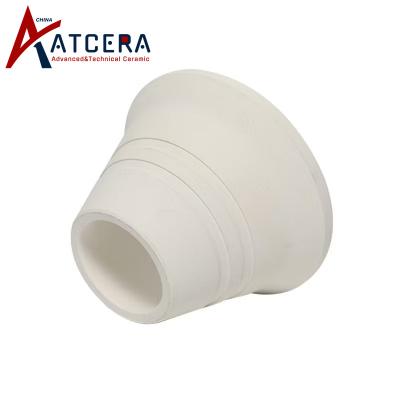

5. Thermal Insulation for Complex Spaces

Perfect for insulating corners and complex spaces, our fiber wool offers unparalleled flexibility and adaptability, ensuring effective thermal and sound insulation in even the most challenging environments.

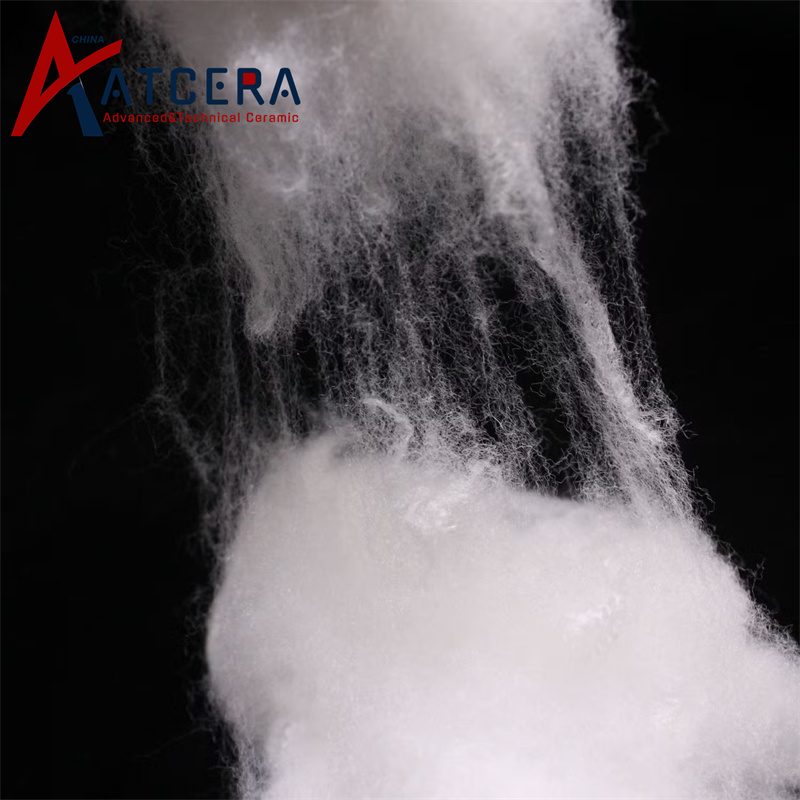

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan.

1. According to your application scenario, analyze the needs, choose the appropriate material and processing plan. 2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand.

2. Professional team, quick response, can provide solutions and quotations within 24 hours after confirming the demand. 3. Flexible business cooperation mechanism, support at least one piece of quantity customization.

3. Flexible business cooperation mechanism, support at least one piece of quantity customization. 4. Quickly provide samples and test reports to confirm that the product meets your needs.

4. Quickly provide samples and test reports to confirm that the product meets your needs. 5. Provide product use and maintenance suggestions to reduce your cost of use.

5. Provide product use and maintenance suggestions to reduce your cost of use.